Click on a project title to find out more.

New ways to tackle some of the biggest health issues we are facing are being developed by researchers utilizing the micro-CT capabilities of UBC’s Centre for High-Throughput Phenogenomics (CHTP). Taking advantage of CHTP’s highest quality x-ray imaging equipment combined with extensive technical support, pre-approved research protocols and access to animal care facilities, researchers are developing new tools to study the progression of chronic obstructive pulmonary disease (COPD) and are investigating the link between obesity and insulin levels.

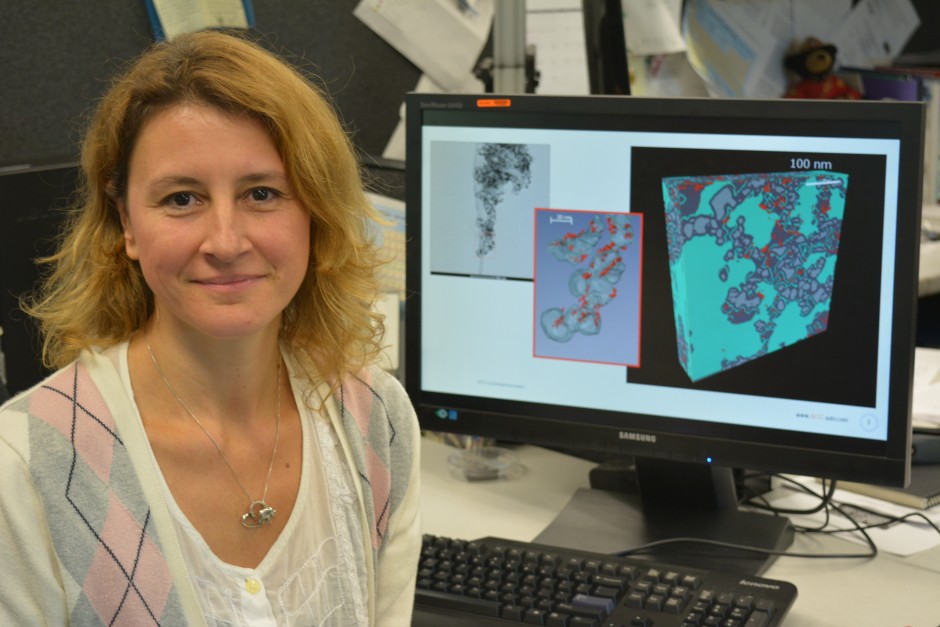

Reducing the use of expensive catalyst materials is vital in developing the next generation of commercially viable fuel cells for vehicles. Dr. Jasna Jankovic of the Automotive Fuel Cell Cooperative Corp. partnered with UBC’s Imaging Lab facilities to visualize and understand the 3D distribution of platinum catalyst particles and other crucial components within fuel cells. By accessing the expert training, assistance and advice of UBC’s technicians and researchers, Dr. Jankovic was able to use the Transmission Electron and Scanning Electron Microscopes to peek into the secrets of the 3D nano-world in order to develop high-performing fuel cells at a significantly lower cost.

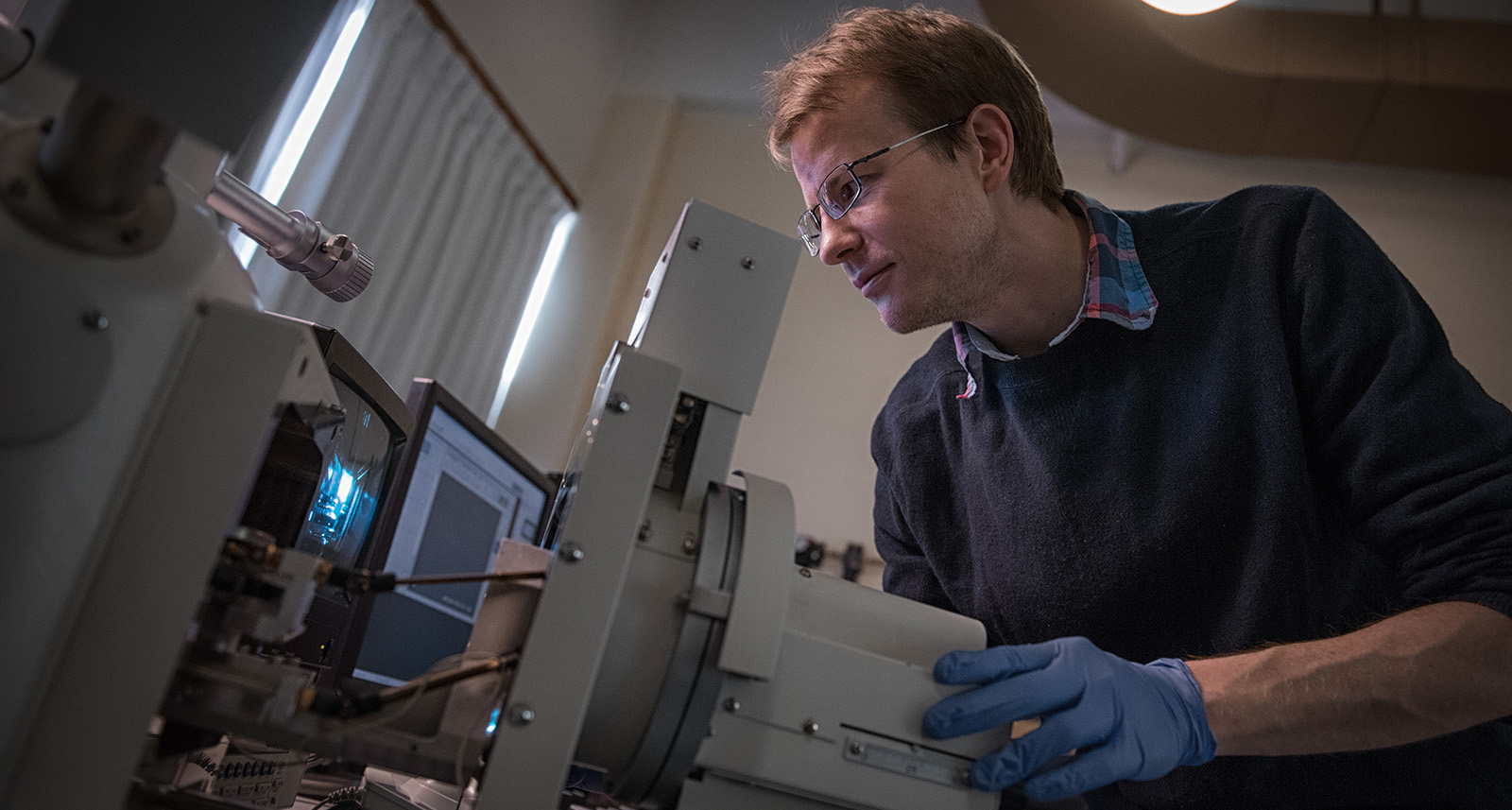

The Bioimaging Facility (BIF), part of UBC Imaging Labs, has a team of technical staff with specialized expertise in operating the Hitachi H7600 Transmission Electron Microscope (TEM) and a wide variety of other imaging equipment to support industry and university researchers. Our team has helped our clients overcome challenges in their projects to get the images they need.

Dr. Christopher Murawsky of Amgen Inc., a leading global biotech company, partnered with UBC’s Imaging Lab facilities to visualize and analyze engineered protein nanoparticles his lab had developed to aid in the discovery of novel therapeutic antibodies. These results contributed to Amgen’s development of a potentially useful tool for the discovery of new antibody-based therapies.

Dr. Wadood Hamad of FPInnovations partnered with UBC’s imaging lab facilities to visualize, investigate and exploit the remarkable properties of tiny non-toxic, renewable cellulose nanocrystals and show how they can improve the performance of nanocomposite materials in aerospace, automotive, marine and energy applications such as windmills.

The Materials EM lab operated under the Department of Materials Engineering offers scanning electron microscopy services as well as basic xray diffraction services. By accessing the expert training, assistance and advice of UBC’s technicians, researchers and a materials engineer, industry quality assurance staff and university researchers can use the information obtained from SEM and EDX imaging and quantitative analysis to investigate materials to understand issues such as material failures and mineral composition.

Jacob Kabel used a scanning electron microscope, equipped with an x-ray detector, to find out why a stainless steel kitchen knife had snapped without warning. High-resolution images and analysis revealed water-induced rust as the culprit.

READ MORE >

Imasco quality assurance manager David Quan worked with UBC’s imaging lab facilities to analyze the concentrations of iron, carbon, chromium, manganese and other elements in three sizes of steel balls used to grind ore in a ball mill.

READ MORE >