Imasco Minerals had an opportunity to buy several hundred steel balls used to crush and grind ore in a ball mill. But the company needed to have accurate and detailed information about the composition of the steel balls to assess whether these would be compatible with its existing ball milling equipment. Imasco quality assurance manager David Quan worked with UBC’s imaging lab facilities to analyze the concentrations of iron, carbon, chromium, manganese and other elements in three sizes of steel balls. The imaging and analysis revealed some important similarities and unexpected differences in the composition of the small balls, compared with the medium and large balls. By accessing the expert assistance and advice of UBC’s lab technicians and researchers, Mr. Quan was able to use a Hitachi scanning electron microscope, equipped with an x-ray detector, to learn that the composition of the various steel balls was similar enough to the ones Imasco currently uses to consider buying them.

David Quan, Quality Assurance Manager at Imasco Minerals Inc. in Surrey, British Columbia, worked with the Materials Engineering Electron Microscopy Lab, part of UBC Imaging Labs, to analyze the elemental composition of three different sizes of metal balls – also known as grinding media — used in ball mill mineral processing equipment to grind ore. Imasco was considering the purchase of several hundred metal milling balls obtained from a decommissioned ball mill to possibly replace existing grinding media used in its own ball mills. “We needed to determine whether the composition of the metal balls was compatible with an existing Imasco ball mill,” says Mr. Quan.

Imasco uses metallic grinding media in its ball mills in the processing of high quality calcium carbonate for products manufactured and sold to the building, agriculture and horticulture industries. “The vendor provided minimal technical information about the grinding media. It’s important to know the composition of the media to avoid introducing possible unwanted contaminants to the product stream. The composition also influences the media’s physical characteristics, such as hardness, which can affect the grinding mechanics in the mill. The analysis at UBC was undertaken to determine whether these different media had a similar composition to our existing media,” explains Mr. Quan.

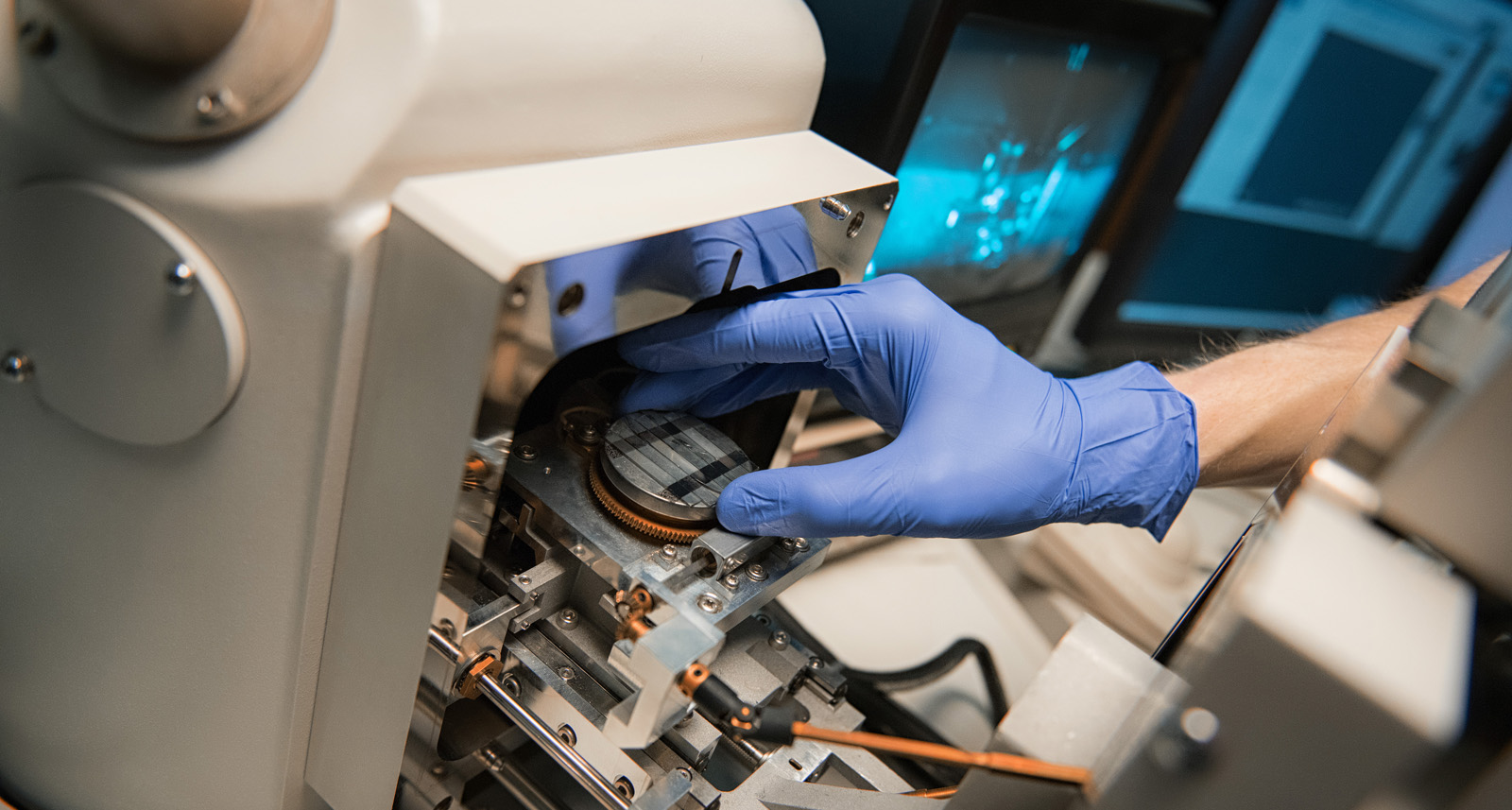

The Materials Engineering Electron Microscopy Lab has technical staff with specialized expertise in operating scanning electron microscopes (SEM) with energy-dispersive x-ray detectors (EDX) for elemental analysis, as well as a variety of other imaging equipment to support industry and university researchers. Training is available on any of the instruments the lab offers. In this project Jacob Kabel, Electron Microscopist and Manager of the Electron Microscopy Lab, used the Hitachi S3000N tungsten filament SEM with an EDX detector to analyze the elemental composition of three metal milling balls of different sizes — small, medium and large — supplied by Imasco.

Going deeper than surface analysis

To prepare the samples for imaging and analysis, the materials engineering machine shop sectioned each of the balls into half segments using wire electrical discharge machining. “You can’t just analyze the surface for this application, given the state of the surface of the balls. You need to look at each of the balls in cross-sections. You want to know what’s in the middle of the ball and determine whether or not it’s the same composition all the way through,” says Jacob.

The half segments of the balls were mounted in phenolic resin, and then ground and polished to a mirror finish. A bare area free of major contaminants or topographic variation was selected for SEM/EDX elemental analysis of the balls. The cross-section images of the three balls revealed some unexpected differences between the small-sized ball, and the large and medium balls. “The small ball was a two-phase material — a high-strength steel made of two separate alloys. The large and medium balls were made of stainless steel,” he says.

Jacob performed a semi-quantitative EDX analysis which showed that the large and medium stainless steel balls were very similar in composition, iron, with small amounts of chromium, manganese and silicon. The two phases in the small high-strength steel ball were somewhat different from each other in their composition. Both were primarily iron, with one phase having higher chromium, a higher amount of carbon and a trace of vanadium, and the other having substantially less chromium.

Passing the composition test

The SEM-EDX analysis was very useful in comparing the composition of the steel balls to the ones that Imasco currently uses. “We learned that the compositions are similar enough to our existing grinding media to consider purchasing the media. The actual shapes and sizes of the media are different from what Imasco currently uses, so more research will have to be done to determine whether the purchase is feasible. Our ultimate goal is to improve process efficiency and the grinding media we’re assessing have passed the first gatepost, which wouldn’t have been possible without the SEM/EDX analysis at UBC,” says Mr. Quan.

SEM particle analysis for quality control

Imasco has worked often with the UBC electron microscopy lab in the past to analyze the many types and sizes of calcium carbonate particles it produces for a wide range of commercial applications. “Jacob is very professional and knowledgeable about what he does and I’ve always had a very good experience working with the UBC imaging labs. It’s important for us to understand and characterize our particles. We need to see the quality of the coating and how it’s distributed on the particle. When we’re looking at such small particles, electron microscopy is the best method and SEM has really helped us,” says Mr. Quan.